Various tests for evaluating concrete quality

Testing should be done for evaluating the concrete quality for the following objectives :-

1. To determine the disparity of concrete quality that is delivered for a given specification.

2. To ensure that either there is adequate strength in concrete or adequate arrangement is made for concrete for stripping, stressing, de-propping, opening to traffic etc.

3. To confirm either the concrete has attained adequate strength for the purpose it is projected for.

There exist different types of test for evaluating diverse qualities of concrete. These tests produce results for their relevant quality of concrete. Therefore, all the tests can’t be carried out at a time because it comprises of cost and time. Therefore, there should clear ideas on the motive of quality tests for concrete. The most crucial test for evaluating the concrete quality is to identify the deviation of concrete quality following the specification provided and mix design throughout concrete mixing and settlement. It will mare sure that exact quality of concrete is arranged at site and with checks for concrete placement prepared, the quality of created concrete members will be as wanted.

Given below, the detailed lists of different tests which are carried out for Concrete Quality:

Tests on hardened concrete:

- Compressive strength (cylinder, cube, core)

- Tensile strength: Direct tension

- Modulus of rupture

- Indirect (splitting) Test

- Density

- Shrinkage

- Creep

- Modulus of elasticity

- Absorption

- Permeability Tests on Concrete

- Freeze/thaw resistance

- Resistance to aggressive chemicals

- Resistance to abrasion

- Bond to reinforcement

- Analysis for cement content and proportions

- In situ tests: Schmidt Hammer, Concrete pull-out, break-off, cones etc.

- Ultrasonic, nuclear.

Tests on fresh concrete:

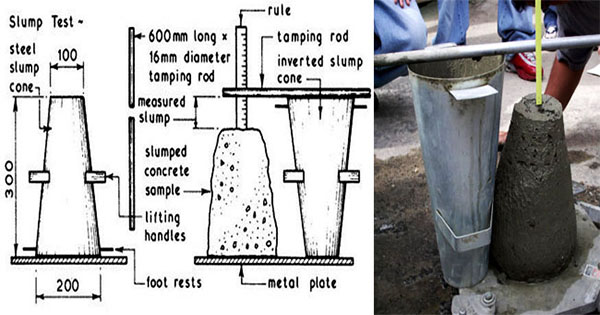

- Workability Tests (slump test and others)

- Bleeding

- Air content

- Setting time

- Segregation resistance

- Unit weight

- Wet analysis

- Temperature

- Heat generation

Among these tests, in practice well more than 90% of all routine tests on concrete are focused on compression tests and slump tests. It is also necessary to carry out fresh concrete temperature and hardened concrete density determination tests.

Why the compressive strength test and slump test in practice are chosen for quality control testing of concrete?

1.All or most other characteristics of concrete are associated with its compressive strength.

2.Compressive strength test is treated as the most convenient, most cost effective or most correctly definable test.

3.Compressive strength testing is most suitable to define the inconstancy of concrete.

4.Slump tests also examine for deviation of construction materials in mix, primarily water-cement ratio.

5.Slump test is simple and rapid to define the quality of concrete prior to arrangement on the basis of suggested slump values for the type of construction.

6.Slump test is most cost-effective as it is performed at site and there is not need for any laboratory or costly testing machine.

7.Slump tests is carried out prior to the disposition of concrete in order that the quality of control is high as excluded mix can be rejected prior to pouring into the structural member. So, it is possible to get rid of disassembly or repairing of imperfect concrete members.

Article Source:- www.theconstructor.org