How to repair your roof efficiently with these useful tips

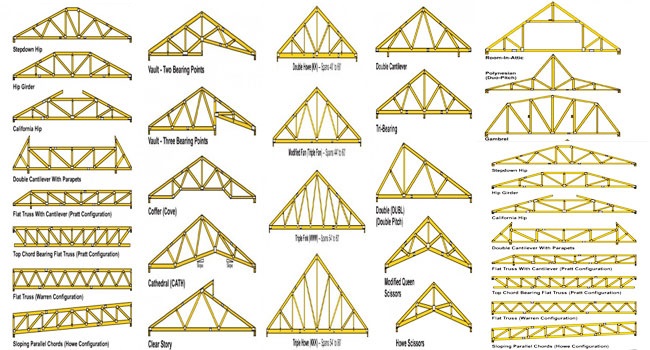

A truss can be defined as the rafter, but it's mainly the shell of the roof that bears the weight of the frame as well as supports the walls of the building. The role of the trusses are very vital as they can resist the walls from bending or flexing. The trusses are mostly crucial for buildings and homes which contain in excess of two stories.

The building trusses are generally affixed jointly with galvanized metal plates and attached together in a triangle shape. In general, the trusses are built up with timber for smaller buildings and houses as it's trustworthy and user-friendly. Sometimes, it also happens that the trusses are formed with aluminum, steel, or another material. In most cases, the budget of the project is based on the materials which are used to form the trusses.

While going to develop your own truss, ensure that everything is organized perfectly with proper tools, materials, equipment and proper process before starting the work. For any confusion, it will be better to employ a professional contractor to create and arrange the trusses.

There exist few different methods for developing trusses. Given below, some elementary guidelines for constructing a hip roof truss that will be treated as your average building truss. Before starting, ensure that you possess the following things:-

- 2x6 or 2x8 timber

- 2x4 timber

- Galvanized steel connector plates (gusset plates)

- Screws (at least 1-1/2 inch)

- 3 inch deck screws

How to select the Timber for the Trusses

- The density of the timber (that will be applied for) will be based on how much weight the truss can undergo. Usually, 2x6 or 2x8 size timber is applied, but 2x4s will be ideal for smaller home additions, sheds, and buildings.

- Buy the timber with superior quality that should be applied with the top chords (two pieces of timber that define the roof's pitch) and the external sections of the bottom cords (bottom pieces of the truss that develop the bottom of the triangle) of the trusses. These will provide support to bear the maximum weight, producing the most stress on the wood.

- Verify for ensuring that the lumber is straight while viewing from one end to the other. If the lumber is curved, ensure that the curve should be placed facing downward with the intension that when the weight is provided on the truss, the curve is flattened out. Be careful to get the bottom of the curve on the top, because it will just bend again with the weight.

To obtain more information, go through the following link.

www.dengarden.com