Various types of structural walls

Masonry walls are categorized as structural walls and rain screen veneer walls. Generally structural masonry walls range from single wythe concrete block or clay brick walls. Single wythe wall has diverse performance capacity against climatic factors, fire, thermal, sound and seismic resistance; as well as construction and maintenance costs. Besides, each wall system contains native attractive characteristics. These wall systems can be customized with the inclusion of supplementary treatments or finishes. Even though high thermal resistance does not present in masonry units, their high mass provides a positive moderating influence on interior temperatures. This "Mass Effect" brings superior dynamic thermal performance as compared to a lightweight wall having the equivalent R-value as well as minimizes the heating and cooling loads.

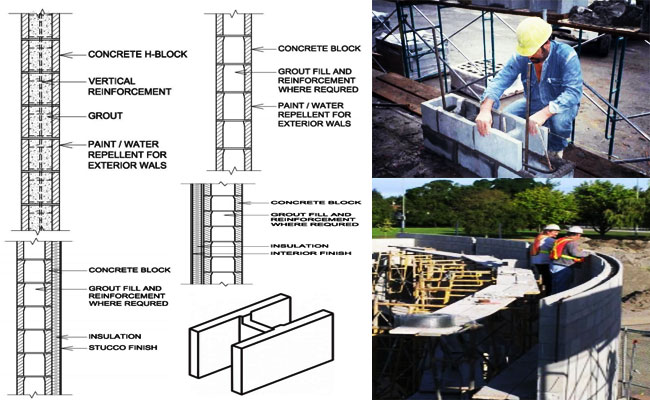

SYSTEM 1: UNINSULATED STRUCTURAL WALL

The void masonry units can be used to produce a cost-effective wall system with a masonry finish on both sides. There are extensive range of finishes which contain various textures and colours of brick and block. Reinforcing for seismic and structural strength is arranged inside the wall. With the latest updating engineering sectors, it is now possible to construct these walls to bigger heights with less reinforcing. The weather resistance capacity of this system is dependent on sound competence for full head and bed joints as well as a concave joint profile and outside wall coatings. Thermal efficiency is sufficient for building types upon low heating requirements.

Benefits:

Cost-effective Wall / Structure

Masonry finish on both sides

Recognizes reinforcing

SYSTEM 2: FULLY GROUTED – H-BLOCK WALL

The H-Block, a special unit, is utilized in this system. It facilitates the flowing of a continuous concrete core in the wall. As there are no end webs, it allows the setting of the block around reinforcing steel and reduces probable head joint leakage. The finished wall contains a strong structural strength and applied in both above and below grade like an inexpensive alternative to formed-in-place concrete walls. Solid filled masonry walls provide support to dryer mass walls and make the performance of the building better. Proper coatings for water resistance should be applied on surfaces under grade or vulnerable to weather.

Benefits:

Monolithic wall that adapts heavy reinforcing

Superior water resistance capacity

SYSTEM 3: INTERIOR INSULATION

If insulation is placed on the interior face of the wall, it considerably enhances the thermal resistance capacity of the standard masonry wall. This system can add air and vapour barriers along with interior finish options. Interior insulation arranges the dewpoint among the insulation and the masonry. If it creates problem then correct moisture management steps should be undertaken. Another useful step is to segregate the insulation from the masonry, making a cavity with drainage and drying potential. Another useful method is to employ sprayed urethane foam as insulation. It is a suitable barrier to resist moisture.

Benefits:

Long lasting exterior

Greater thermal performance

SYSTEM 4: EXTERIOR INSULATION

The use of insulation to the outside of the wall together with the mass of the masonry on the interior brings greater thermal efficiency and resistance against rain on the basis of the exterior finish applied.

Benefits:

Superior thermal performance from insulation and exposed interior mass

Better water resistance capacity

Article Source

www.masonrybc.org