Some useful tips to verify the quality of cement on construction site

While making initial examination, it becomes essential to verify the quality of cement on site. Sometimes, it becomes difficult to examine all the engineering qualities of cement on construction site but one can get a fair idea concerning the quality of cement by applying some field tests. These field tests can be performed on the construction site for evaluating the quality of cement.

Given below the details of field test: -

- Date of packing

- Colour

- Rubbing

- Hand Insertion

- Float Test

- Smell Test

- Presence of lumps

- Shape Test

- Strength Test

Field Tests on Cement

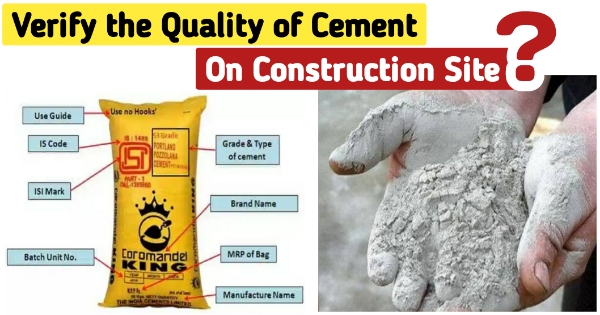

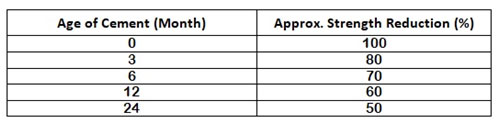

Date of Packing: -Date of manufacture should have been clearly mentioned on the bag. It is very crucial since the strength of cement gradually decreases in due course of time.

Colour: -The cement should contain consistent colour. Normally, the colour of cement remains grey containing a light greenish shade. The colour of cement provides a hint of extra lime or clay and the degree of burning.

Rubbing: -Select small quantities of cement among fingers and rub it to check whether it feels smooth or rough. If it feels rough, it signifies adulteration with sand.

Hand Insertion: -Put your hand into the cement bag and if it feels cool, it means that no hydration reaction occurs in the bag.

Float Test: -Put a small amount of cement in a bucket of water. If the quality is good, the cement will submerge and should not float on the surface.

Smell Test: -Select a bit of cement and fragrance it. If the cement includes lots of pounded clay and slush like an adulterant, there will be an earthy smell in the paste.

Presence of Lumps: -Open the bag and check that no lumps exist in the bag. It will make sure that no setting has happened.

Shape Test: -Select 100g of cement and produce a stiff paste. Make a cake with sharp edges and place it on the glass plate. Submerge this plate in water. Verify properly that the shape shouldn’t get damage at the time of settling. It should have the capacity to set and retain strength. Cement can be set under water also and for this reason it is also described as ‘Hydraulic Cement’.

Strength Test: -A block of cement with dimension 25 mm x 25 mm and 200 mm long is formed and it is submerged for 7 days in water. It is then arranged on supports 15000 mm apart and it is loaded with a weight of 340 N, the block should never demonstrate any sign of failure.