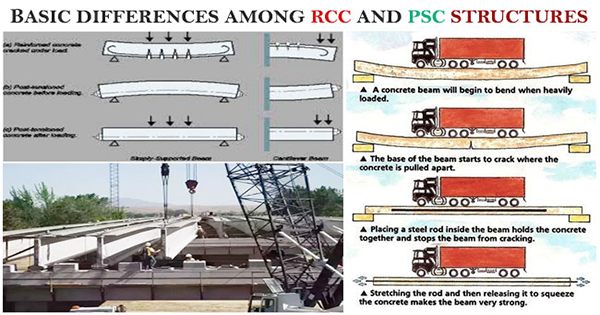

Basic differences among RCC and PSC structures

In this civil engineering article, you can know the variations among RCC and PSC structures.

REINFORCED CONCRETE:

- Reinforced Concrete (RC) stands for a composite material in which the low tensile strength and ductility of concrete are confronted with the use of reinforcement that contains greater tensile strength and ductility.

- The reinforcement is normally, though not inevitably, steel reinforcing bars (rebar) and it is generally implanted in the concrete prior to setting the concrete. Modern reinforced concrete can include different reinforcing materials which are formed with steel, polymers or alternating composite material along with rebar or not.

- Reinforcing schemes are normally designed to withstand tensile stresses in specific areas of the concrete that can lead to unnecessary cracking or structural collapsing.

PRESTRESSED CONCRETE:

- P.S.C. stands for a structural concrete in which internal stresses are provided to lessen possible tensile stresses in the concrete caused by loads.

- This compression is formed with the tensioning of high-strength "tendons" situated within or next to the concrete volume, and is provided to make the performance of the concrete better in service.

- Tendons comprise of single wire, multi-wire strands or threaded bars, and are normally created from high-tensile steels, carbon fibre or a ramid fibre.

ADVANTAGES OF P.S.C OVER R.C.C

- P.S.C. is more long-lasting as no tensile cracks exist there, while in R.C.C tensile cracks are inevitable, that's why adverse environmental effects may occur.

- Since high strength concrete is applied as well as dead load moments can be nullified, dead weight of P.S.C. member remains less with regards to what is necessary for R.C.C. member. The dead weight of P.S.C member is about one-third of similar R.C. members.

- The material cost in P.S.C. is significantly less as compared to that in similar R.C. members.

- The distortion of P.S.C. members is much less with regards to that for similar R.C. member. For beams deflection of P.S.C. beams remains about one - Fourth of that of similar R.C. beams.

- P.S.C contains greater resilience i.e. a substantial strength for recovering entirely from the impact of infrequent overloading, devoid of any severe harm. For P.S.C. cracks in such circumstances which are created temporarily will close up fully.

- The fatigue strength of P.S.C. is superior.

DRAWBACKS OF P.S.C. OVER R.C.C

- It needs skilled labour and greater quality control.

- It necessitates special method to employ pre-stressing forces and fasten the wires.