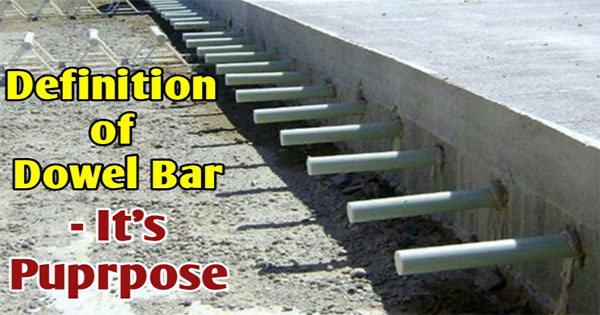

Definition of Dowel Bar - It's objective and applications

Dowel bars stand for short steel bars which are mostly utilized in concrete pavements to retain a mechanical connection among slabs devoid of keeping the horizontal joint movement restricted. The bars are provided among two concrete slabs to transmit the loads among the two slabs and facilitate any horizontal movement owing to expansion.

They make the load transmission better by facilitating the leave slab to presume some of the load prior to the load is enforcing over it practically. As a result, the joint deflection and stress are minimized in the approach and leave slabs.

Dowel bars are arranged at the transverse joints of concrete pavement and are involved in the partial transmission of wheel load from one slab to its adjoining slab.

Loads bars are expanded from an RCC member with the intention that in the future when the RCC member is enlarged, the reinforcement of the extension is connected with these bars.

The length of dowel bars in compression remains 45 times bar dia and in tension it is retained as 52 times the bar dia.

The objective of Dowel Bar:

- To deliver the load from one slab to its adjoining slab with the purpose of moving two successive slabs simultaneously and minimizing the impact loading produced by the slabs with their independent movement.

- To minimize joint faulting and corner cracking.

- To improve the functioning of pavement joints.

Benefits of Dowel Bars

- Minimizes deflection and stresses.

- It raised the load-bearing strength of slabs.

- It improves the initial pavement life.

The effective depth is calculated from the face of the member to the centre of area of main reinforcement. Therefore, Effective cover = Clear cover + (Dia of Stirrups/links) + (Dia of main reinforcement bars) + 0.5*(distance among bars).