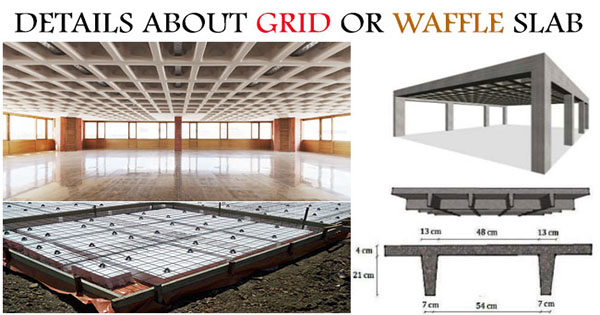

Details about grid or waffle slab

This civil engineering article mainly highlights the details about waffle slab (definition, benefits and drawbacks).

The waffle slab refers to the family of reinforced concrete slabs which are lightweight and non-homogeneous and reinforced in two orthogonal directions to develop a ribbed plate. It comprises of square grids having deep sides.

The waffle slab can support distributed and point vertical actions as well as horizontal actions to a fewer extent.

The waffle slab is mostly found in entryway of hotels, malls, restaurants to obtain nice realistic view and set up artificial lighting as well as airports, parking garages, commercial & industrial buildings, bridges, residence and other structures for which additional strength is essential.

There are empty holes in the slab while detaching the formwork.

Initially, PVC trays alias pods are arranged on shuttering. After that, reinforcement is arranged among the pods along with steel mesh at the top of the pods. Then the concrete is filled. Once the concrete is settled, the formwork is eliminated except of PVC pods. It produces hollow holes in it where hole is sealed at one end.

The waffle slab offers the following benefits:-

- It is adaptable.

- It is lightweight and as a result less foundation costs is required.

- It has sound crack and sagging resistance capacity.

- It can sustain significant amount of loads with reference to commonly used concrete slabs.

- The construction process is very fast.

- It is very endurable.

- It has superior vibration control.

- It has good fire resistance capacity.

Characteristics of waffle slab:-

- It is suitable for flat sites.

- No need to provide beam excavation.

- No need to utilize controlled or rolled fill.

- Cardboard slab panel or empty formers are applied.

- Slab panels are provided on 1 metre grids (roughly).

- Trench mesh or separate bars can also be applied.

- The depth of slab varies from 85 to 100 mm.

- Width of inside beams range from 110 to 200 mm.

- There is nominal concrete volume.

- Shrinkage of slab is lesser as compared to stiffened rafts and footing slabs.

- It consumes 30% less concrete as compared to hardened raft.

- It consumes 20% less steel as compared to hardened raft.