How to set up rate analysis for RCC work

Learn the detailed steps for rate analysis for Reinforced Concrete (RCC) work. To start with, you have to first make estimation of labour, materials, equipments and various items for specific quantity of reinforced concrete.

The next step should be finding out the elements of structure to whom the RCC rate analysis will be applicable, because the quantity of reinforcement steel fluctuates with slabs, beams, columns, foundation, RCC Roads etc., whereas the quantity of other materials like sand, coarse aggregate and cement are unchanged with the similar mix design (mix proportion) of concrete. Since the quantity of reinforcement steel varies, labour rates for reinforcement work modifies as per type of structural component. The Quantity of materials similar to sand, cement and coarse aggregates fluctuate with mix design like M15 (1:2:4), M20 (1:1.5:3), M25, M30 etc..

Learn how the rate analysis for 1m3 of reinforced concrete is done.

Necessary data for RCC Rate Analysis:

1. Calculation of materials:

Material should be calculated for sand, cement, coarse aggregate and steel for a specific mix design. For calculation purpose, assume a mix design of 1:1.5:3. The dry volume of total materials needed is taken as 1.54 times the wet volume of concrete, by reason of existence of voids in sand and aggregates in dry stage. So, for calculation purpose, take the total volume of materials necessary as 1.54 m3 for 1m3 of wet concrete.

a) Bags of cement necessary:

Volume of cement necessary for 1m3 of Concrete =

![]() =0.28 m3

=0.28 m3

Then number of bags of cement (volume of each bag of cement = 0.0347 m3)

=![]() = 8.07 bags of cement.

= 8.07 bags of cement.

b) Volume of Sand necessary:

Volume of sand necessary =![]() = 0.42 m3 of sand.

= 0.42 m3 of sand.

c) Volume of Coarse Aggregate Necessary

Volume of Coarse Aggregate =![]() = 0.84 m3 of coarse aggregates.

= 0.84 m3 of coarse aggregates.

d) Computation of Reinforced Steel:

Various components of structure like slabs, beams, columns, foundations, roads etc are considered as vital parts to determine the quantity of steel necessary. Two processes are used to calculate the required steel quantity.

As per First method, on the basis of the accessible drawing, you can compute the total weight of steel necessary by dividing with total volume of concrete for various components. It will provide you the weight of reinforcement steel per cubic meter of concrete.

As per Second method, the percentage of reinforcement for various components is presumed. Given below, the percentage of reinforcement steel that is usually necessary per diverse components. It’s values will differ from structure to structure, and can be supposed from previous experiences of equivalent structure.

- For slabs = 1.0 % of concrete volume.

- For Beam = 2 % concrete volume.

- For column = 2.5 % of concrete volume.

- For RCC Roads, 0.6% concrete volume.

For RCC Column, the reinforcement required is 2.5% of concrete volume. Find out the weight of steel with the following formula:![]() =196.25 kg.

=196.25 kg.

2. Labour Requisite for 1m3 of RCC:

Labours required are demonstrated on the basis of days required by specific labour to finish its work for the specified quantity of concrete. The following types of labours are necessary:

a) Mason: According to Standard Schedule of Rates and Analysis of Rates, One mason is essential for 0.37 days.

b) Labours: One Unskilled labour is essential for 3.5 days.

c) Water carrier: One water carrier essential for 1.39 days.

d) Bar Bender: Bar bender requirement is based on weight of reinforcement. Here, assume one bar bender necessary for 100 kg of steel as for 1 day.

e) Mixer Operator: One mixer operator is necessary for 0.0714 days.

f) Vibrator Operator: One vibrator operator is necessary for 0.0714 days.

3. Equipments and sundries:

Equipment and other charges, like water charges, sundry items, tools and tackles etc are presumed as some percentage of total cost of materials and labours. Assume it as 7.5%.

4. Contractor’s Profit:

Contractor’s profit may fluctuate according to place to place, organization to organization and work to work. It differs from 10 – 20%. In this case, presume it as 15% of total cost of materials, labours and equipments.

From the above steps, the quantity of each item is computed. To accomplish rate analysis of RCC, each quantity should be multiplied with their rates to obtain the amount for each item of work. Rates fluctuate from place to place and time to time. It is suggested to presume local rates or standard rates of the place.

Download RCC Rate Analysis Spreadsheet

To obtain the rate or cost for 1m3 of concrete, all the four items described above should be summed.

Article Source

theconstructor.org

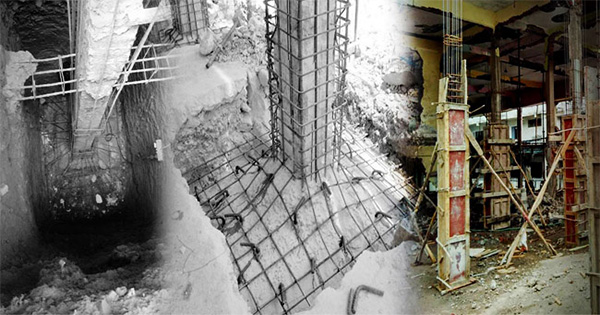

Image Courtesy : www.lipiinfra.com