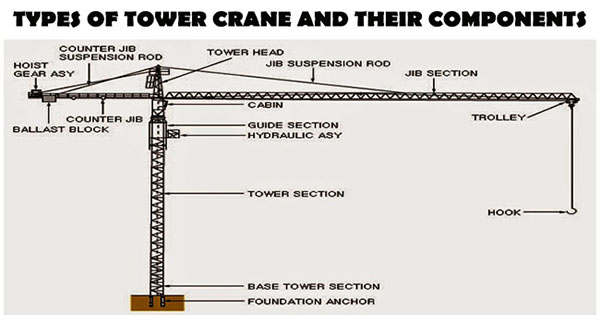

Types of Tower Crane and their components

Tower cranes stand for an advance type of balance crane that is made of the similar basic elements. These are attached to the ground on a concrete slab (and often joined with the sides of structures), and provide the best alliance of height and lifting strength. They are frequently utilized in building up the construction of tall buildings. The base is then secured with the mast to provide the height for the crane. Besides, the mast is joined with the slewing unit (gear and motor) that facilitates the crane to revolve. On top of the slewing unit, three main parts exist which range from the long horizontal jib (working arm), shorter counter-jib, and the operator's cab.

The best use of tower crane location in the construction sites significantly influences the material transportation costs of a project.

The long horizontal jib belongs to the section of the crane that bears the load. The counter-jib sustains a counterweight, normally of concrete blocks, whereas the jib interrupts the load to and from the center of the crane. The crane operator either stays in a cab at the top of the tower or manages the crane through radio remote control from the ground. In the first case, the operator's cab is generally situated at the top of the tower connected to the turntable, but can be fixed on the jib, or partway down the tower. The lifting hook functions with the crane operator by applying electric motors to operate wire rope cables through a system of sheaves. The hook is situated on the long horizontal arm to elevate the load along with its motor.

Elements of a Tower Crane

Tower cranes are mostly found in construction and other industry to lift and move materials. Several types of tower cranes are available. Though the types differ, but the main sections are the similar like below:-

- Mast:It is the prime supporting tower of the crane. It is built with steel trussed sections which are secured jointly throughout installation.

- Slewing unit:The slewing unit rests at the top of the mast. It is the engine that allows the crane to rotate.

- Operating cabin: On major tower cranes, the operating cabin rests just over the slewing unit. It comprises of the operating controls, load-movement indicator system (LMI), scale, anemometer, etc.

- Jib: The jib, or operating arm, expands in horizontal direction from the crane. A "luffing" jib has the capacity to move up and down; a fixed jib contains a rolling trolley that moves along the base to transfer goods horizontally.

- Counter jib: It sustains counterweights, hoist motor, hoist drum, and the electronics.

- Hoist winch: The hoist winch assembly comprises of the hoist winch itself (motor, gearbox, hoist drum, hoist rope, and brakes), the hoist motor controller, and supporting components like the platform. Various tower cranes contain transmissions with two or more speeds.

- Hook: The purpose of hook (or hooks) is to join the material to the crane. It is hanging from the hoist rope either at the tip, for luffing jib cranes, or in the hoist rope belly below the trolley for hammerhead cranes.

- Weights: Large concrete counterweights are affixed toward the back of the counter-deck, to make up for the weight of the goods lifted.