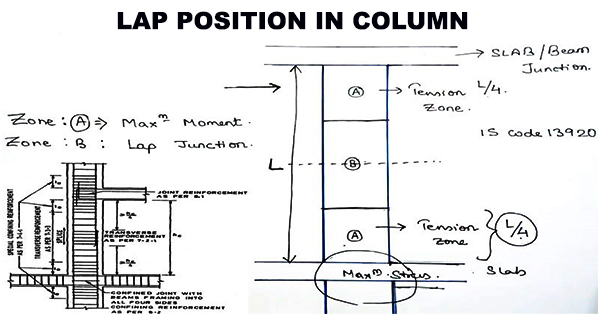

How to arrange proper lapping in column in exact position

Get some useful information on reinforcement lapping zone in column through this construction video tutorial. The video will teach you the process for arranging lap in column in proper location on the basis of IS code 13920.

If two segments of reinforcing bar (rebar) are coincided to form a constant line of rebar, then lap should be provided. The lap length varies with different factors like the concrete strength, the rebar grade, size, and spacing.

The lap is formed to transfer load from one bar to another bar and sustain continuity. The placement of lap is influenced by the bending moment of the column.

The lap length is normally the overlapping at the end of bars and captured as 45 to50 X d where d indicates the diameter of the rod. This length is decreased if the rods are welded. It resists the collapsing of the columns and beams. Lap length changes as per tension and compression zones and mainly dependent on grade of concrete and steel.

Rebars in column are lapped at around 5 feet from the story because of workability.

Due to lateral forces and interstory drifts, columns produce maximum moments at the top and bottom of the story. Now, the bars can’t be lapped into the joint because those are the locations of heighest stresses. Therefore, the most effective position is around 5 ft from story height.

According to the standard I.S. 13920, vertical bars of columns must have been lapped in regular zone (Mid-height ) only and it should have been expanded that is not above 50% of bar is lapped at one section. The undermost clear vertical distance amid lap bars should remain 0.25 times lap length.

In the following video tutorial, Mukesh Shah, the eminent civil engineer briefly explains the reinforcement lapping zone in column.

Video Courtesy : L & T - Learning Technology