Types and grades of steels as per IS Code 456 : 2000

In this construction video tutorial, you will gather knowledge on various types and grades of steel with adherence to IS 456:2000 standard.

We know, concrete is casted in jobsite whereas the steel normally is developed in factory under controlled condition. So, the process is simple and superior for quality control of steel.

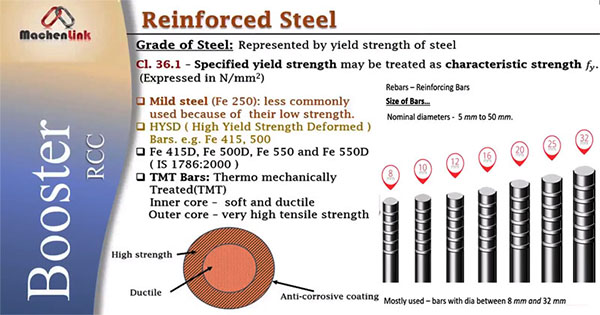

We frequently apply reinforcing bars alias rebars to demonstrate steel bars.

Size of bars

In India, nominal diameter of steel varies from 5 mm to 50 mm. But steel bars having diameters 8 mm to 32 mm are extensively utilized.

On the basis of surface, the steel bars are categorized as follow :-

Plain bars which contain smooth surface and deformed bars which contain harsh surface or lugs on their surface. Lugs are useful to make the binding among steel and concrete better.

Grade of steel

Grade of steel is illustrated with yield strength of steel. According to clause 36.1 of IS Codes, specified yield strength is defined as characteristic strength (fy) that is stated in N/mm2.

Given below, the different grades of steel bars :-

Mild steel (Fe 250) – He Fe denotes iron and 250 denotes yield strength in megapascal. It is not recommended because of it’s poor strength.

HYSD alias High Yield Strength Deformed Bars (Fe 415, 500)

Some newly launched grades of steel bars are Fe 415D, Fe 500D, Fe 550 and Fe 550D with adherence to IS Code 1786 : 2000. Here, D denotes greater ductility. These contain superior strength.

There are other strong steel bars which have good resistance capacity against corrosion. These are known as TMT bars alias Thermo mechanically treated bars. Inside core of these bars is soft and ductile and exterior core contains extreme tensile strength. These bars also comprise of anti-corrosive coating.

To gain more knowledge, go through this exclusive construction video tutorial presented by MachenLink.

Video Courtesy : MachenLink